Applications

- Annealing

- Sintering

- Diffusion

- LPCVD

- Oxidation

- Glass-to-metal sealing

MATERIALS

- Ceramics

- Glass

- III - V

- II - VI

- Sapphiire

- Superconductors

- GaN

- SiC

- Metal

- Quartz

- Silicon

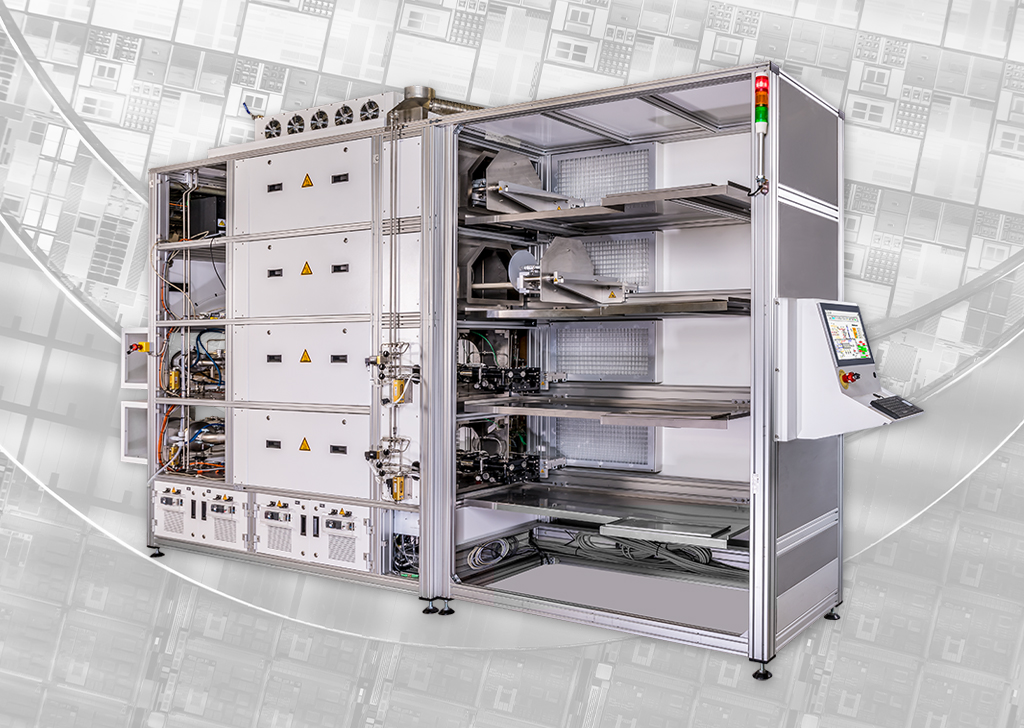

Tubestar: Batch-Type Horizontal Furnace

ECM Tubestar is the compact batch-type tubular furnace from ECM Lab Solutions. The key characteristics of this furnace line are:

- Precise thermo-chemical treatments combined with industrial process control

- Integration modularity

- User-friendly interface

Each populated chamber can be independently configured and operated in a large range of atmospheric, sub-atmospheric or low pressure processes. The Tubestar furnace can also handle multiple gases and liquid precursors with a temperature range from 200°C to 1300°C. Its modular design allows to meet a large range of clean thermal treatments for R&D and small production facilities.

Benefits

- Primary vacuum pump & Secondary vacuum pump

- Atmospheric configuration (reduced, low pressure or ultra-high vaccum)

- Wet oxidation

- By-product treatment systems

- Turbomolecular pumping assembly

- Water cooling unit

- Possible robotics and advanced automation integration

Specifications

- Modular and flexible & tiny footprint

- 1 to 4 independent process chambers

- Configurable for 25/50 or 50/100 wafers per chamber

- Manual or automatic boat loading

- Temperature range (up to 1100°c - 1200°c upon request)

- Minimized heat load around the system

- Overall dimensions (L*W*H) 1500*800*1500 mm

- Teflon type, Oil type or Dry Pump

- Compatible with 156X square substrate (PV)

- Spike and profile thermocouple control

- Loading platform, Handling tool

- Multizone heating element

- Atmospheric or vacuum process capability

- Gas Cabinet for up to 13 gases

- Liquid source precursor Cabinet and vaporization

- SEMCO Mycro process Management software