4th HT&SE INTERNATIONAL CONFERENCE & EXPO, CHENNAI (2023)

Visit Stall No. S5

ECM Technologies is a World’s Leading vacuum furnace manufacturing Company & ECM India Is a Subsidiary of ECM Technologies, France.

KNOW MOREKnow more about various heat Treatment processes

Low pressure carburizing (LPC), also known as vacuum carburizing or vacuum case hardening is achieved under vacuum, in a vacuum furnace.

Low pressure carbonitriding (LPCN) is a thermo-chemical surface treatment in which Nitrogen – obtained from ammonia NH3 dissociation – interacts with carbon during the three phases

Ferritic Nitro-Carburizing (FNC) is a thermochemical surface hardening process using diffusion of both nitrogen and carbon into the heat-treated part. This treatment is mainly used to improve wear and fatigue resistance ...

At its root, vacuum sintering involves two things: a vacuum furnace and a combination of metallic powders. By using one properly and mixing the other in the right proportions, several useful properties can be promoted.

By Definition, brazing is a process which consists in joining two metallic items by melting a filler metal used as a joint,such as copper, cobalt or nickel. This metal joining process takes place at high temperature,in a controlled atmosphere or under vacuum, to insure homogeneity and quality of the process.

Nitriding is a thermochemical treatment that diffuses nitrogen into the surface of metals. It is used on ferrous, titanium, aluminum, and molybdenum alloys, but most commonly on low-carbon, low-alloy steels.

Our vacuum induction melting (VIM) or vacuum arc remelting (VAR) furnaces are designed to develop new materials for melting metal alloys, glasses, silica, refractory materials, and oxidizing .......

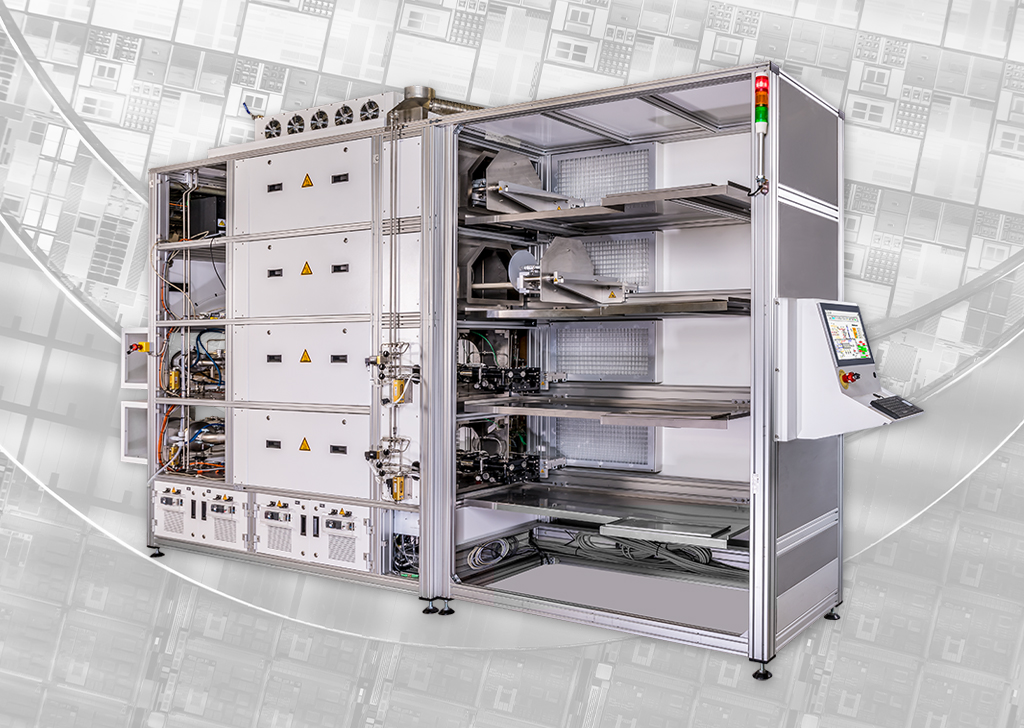

Various Vacuum Furnaces Available

Our Flex is the most innovative and popular solution of ECM’s Low Pressure Carburizing furnace range.

Learn more

The new Eco Vacuum Furnace product line makes your heat treating a cleaner, safer, and more efficient operation.

Learn more

The ECM Nano vacuum furnace is the latest product in the range of Low Pressure Carburizing and carbonitriding furnaces.

Learn more

Our Mono vacuum furnace consists of one heating cell using our patented INFRACARB® process for low pressure carburizing and low pressure carbonitriding.

Learn more

Cristal furnaces are dedicated to heat treating under vacuum at high temperatures.The enclosure is insulated with specific metals, with a possible choice of molybdenum or tungsten resistors.

Learn more

Lilliput furnaces take over the characteristics of most ECM furnaces but adapt them to the numerous conditions of laboratory experiments.

Learn more

ECM Tubestar is the compact batch-type tubular furnace from ECM Lab Solutions.The key characteristics of this furnace line are: Precise thermo-chemical treatments combined with industrial process control Integration modularity User-friendly interface

Learn more

Heat treatments carried out in the ECM Technologies Turquoise vacuum furnaces are specifically tailored to alloys prone to oxidation: Nickel, Titanium, Cobalt, Chrome, Molybdenum as well as Tungsten.

Learn more

ICBP® Jumbo is the biggest design solution of our low pressure carburizing furnace range. It maintains all the compact and modular qualities of the ICBP® Flex however, design goes further in terms of volume and number of parts treated in a low pressure carburizing installation.

Learn moreECM India has over 44 + heat cell install all over India With major OEM & tier one company Also World Wide ECM Technologies has more then 1600 + installation & all are running successfully. Huge Reference compnanies worldwide using ECM Vacuums Furnaces. We delivered what we commit.

28-30 SEPTEMBER

28-30 SEPTEMBER

Visit Stall No. S5

Novenmber 2

Novenmber 2

--

--